When you first step into the world of industrial production, automotive repair, or even consumer goods, one of the most common confusions arises around the roles of a parts company versus a manufacturer. On the surface, both seem to do the same thing: provide parts. But if you dig deeper, you’ll see their responsibilities, business models, and value propositions differ significantly.

As someone who has worked with both a plastic parts company and a plastic molded parts manufacturer, I’ve seen firsthand how these distinctions affect everything from cost efficiency to supply chain reliability. Let’s break it down in a way that’s practical, relatable, and useful, especially if you’re trying to decide which kind of partner you need for your project or business.

The Core Difference in Their Roles

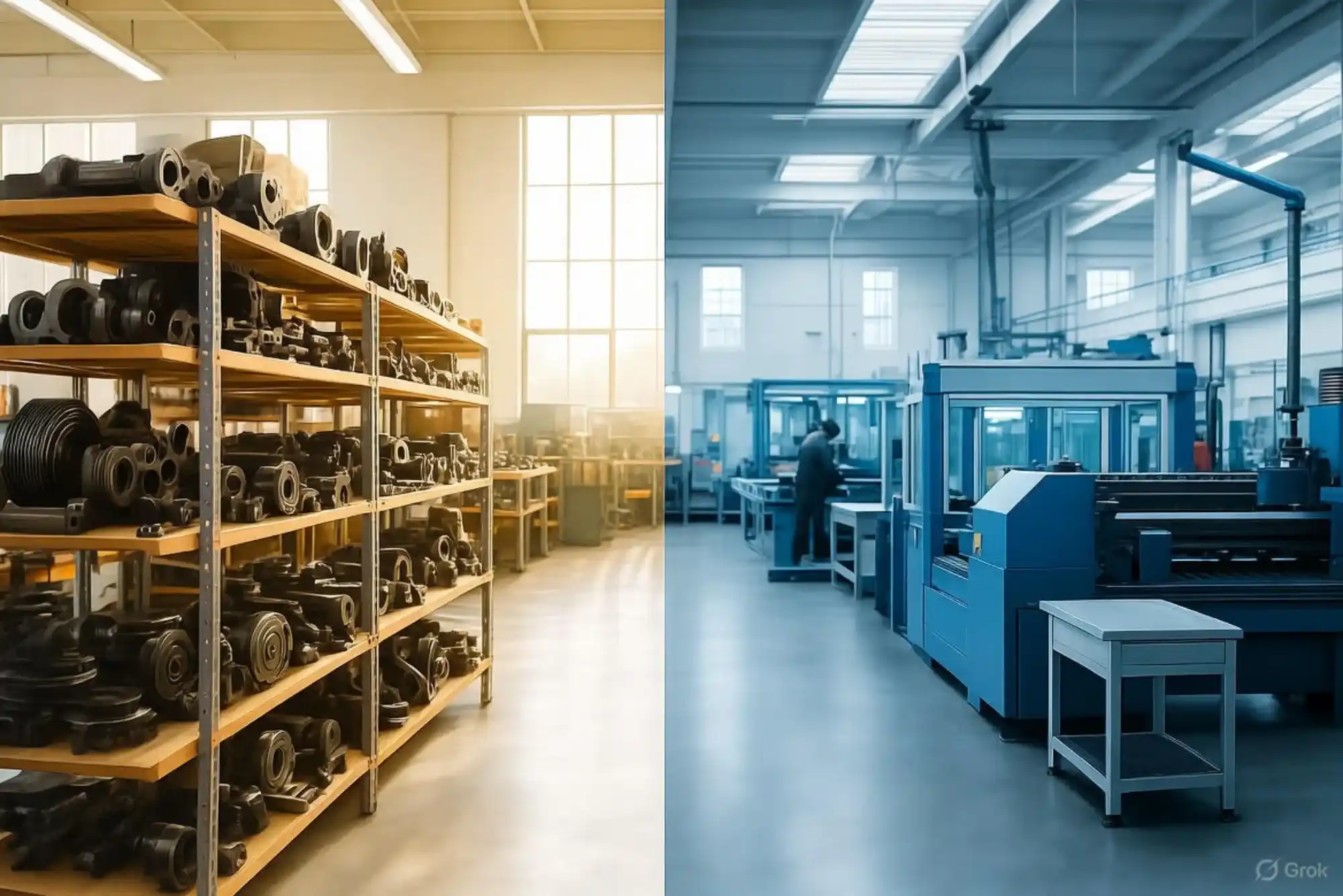

At its simplest, a manufacturer is responsible for creating parts, while a parts company specializes in distributing them. A plastic molded parts manufacturer will design, engineer, and produce items using their own machinery, molds, and expertise. They control the technical process—everything from sourcing raw materials to ensuring the molded part meets strict industry standards.

A plastic parts company, by contrast, doesn’t usually produce items directly. Instead, it sources them from manufacturers, manages inventory, and sells them to end users or other businesses. Think of them as the link between production and consumption.

This difference may sound small, but in practice it shapes the way each operates and what kind of value they bring to the table.

The Manufacturer’s Perspective

Manufacturers are the backbone of production. If you’re dealing with a plastic molded parts manufacturer, you’re connecting directly with the people who shape molten plastic into precise components. These companies invest heavily in tooling, molds, and injection machines. They also employ engineers who understand the intricacies of material selection, stress resistance, and dimensional accuracy.

One of the biggest advantages of working with a manufacturer is customization. If your project requires a specialized component—say, a part that must withstand heat, impact, or specific chemical exposure—a manufacturer can design and mold it to your exact requirements. A plastic molded parts manufacturer isn’t just selling you a product; they’re offering you technical expertise and production capacity.

However, manufacturers often require minimum order quantities (MOQs). Because of the cost of setting up molds and production runs, they typically don’t cater to very small or one-off orders. This is where a parts company often steps in.

The Parts Company’s Perspective

A plastic parts company operates differently. Instead of producing parts themselves, they act as suppliers or distributors. Their value lies in accessibility. They stock a wide variety of items sourced from multiple manufacturers, making it easy for customers to get what they need without navigating the complexities of factory orders.

For example, if you need just 20 replacement parts for an old machine, reaching out to a plastic parts company makes more sense than contacting a plastic molded parts manufacturer that might require a minimum order of thousands. Parts companies are built to serve clients with smaller needs, urgent deadlines, or diverse product requirements.

They also play a critical role in the supply chain by holding inventory. Instead of waiting weeks or months for a production cycle, you can often find what you need off the shelf through a parts company. That speed and convenience are invaluable for businesses that can’t afford long downtimes.

Where the Lines Blur

In practice, the distinction between a plastic molded parts manufacturer and a plastic parts company isn’t always so rigid. Some manufacturers also run distribution arms, effectively acting as both producer and supplier. Similarly, certain parts companies may commission private-label production from manufacturers, meaning they design a part but outsource the actual molding.

This overlap can make it tricky to determine who you’re really dealing with. When choosing a partner, it’s important to ask direct questions:

-

Do you manufacture the parts in-house, or do you source them?

-

Can you provide documentation on the production process?

-

What’s your typical lead time and minimum order size?

The answers will help you identify whether you’re working with a true manufacturer or a distributor.

Real-World Example: Automotive Industry

Let’s take the automotive industry as an example. Suppose you’re restoring an older vehicle and need plastic clips or trim pieces. A plastic parts company is the go-to option because they can supply off-the-shelf items from multiple manufacturers, often with same-day delivery.

Now imagine you’re developing a brand-new vehicle model and require unique, custom-molded interior components. This is where a plastic molded parts manufacturer becomes indispensable. They can design and produce components tailored to the car’s aesthetic and structural requirements, ensuring consistency across thousands of units.

Which Should You Choose?

The decision comes down to your specific needs:

-

If you need standard parts quickly and in smaller quantities, a plastic parts company is usually the better choice.

-

If you need custom designs, technical expertise, or large-scale production, a plastic molded parts manufacturer is the partner you want.

In many cases, businesses use both. A startup might begin by sourcing off-the-shelf parts from a distributor to keep costs low, then later transition to working with a manufacturer once demand grows and custom solutions become necessary.

Final Thoughts

Understanding the difference between a parts company and a manufacturer is more than just industry jargon—it’s about making smart business decisions. A plastic parts company makes it easier to access diverse, ready-to-ship products, while a plastic molded parts manufacturer offers the ability to innovate and control quality from the ground up.

Both play essential roles in the modern supply chain, and the right choice depends on whether your priority is convenience or customization. From my own experience, the businesses that thrive long-term are the ones that know when to leverage each type of partner strategically.